Assembly line - Gravity Track

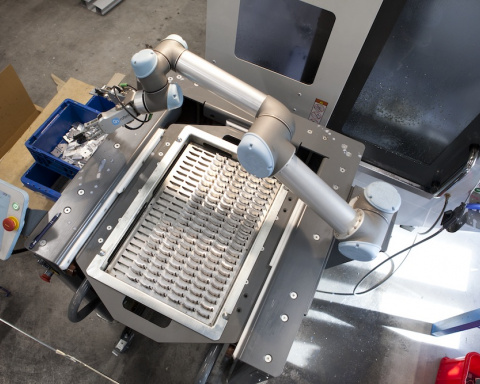

Customer request:

- A low-cost solution for moving KLT boxes with cable assemblies from the platform down, without the need for the forklift operators.

- Decrease resp. eliminate the possibility of an error when using the correct cable assembly by the operator.

Pre-solution status:

- The customer moved the KLT boxes containing cable assemblies from a landing platform down to the assembly line operator using a forklift.

- Despite the marked positions of the boxes in the trolley, the cable assemblies were often confused by the operators.

Implemented solution:

- The designed Slope track is based on magnets. The Gravity Track moves the KLT boxes directly to the operator's position and avoids confusion. It keeps the time and holds 14 boxes instead of 12.

- The device is a "karakuri" solution, which means besides low input costs also very simple maintenance without theinput energy (air, electricity...).

Benefit for the customer:

- Increase in the number of filled boxes.

- No need to use the forklift operators.

- Decrease in the assembly errors.

- Lower input costs.

Solutions

Our goal is to provide our customers with a wide-range portfolio of services - from initial consultations, through design, project development, application software development, software development, delivery, installation, testing, staff training, to warranty and post-warranty service and maintenance. Thanks to our offer of complete services we have a long list of satisfied clients.