Dedusting of sintering belts

Customer request:

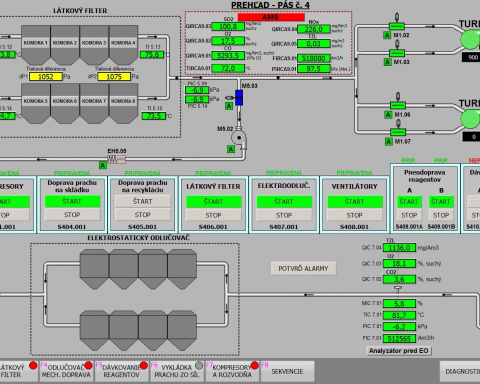

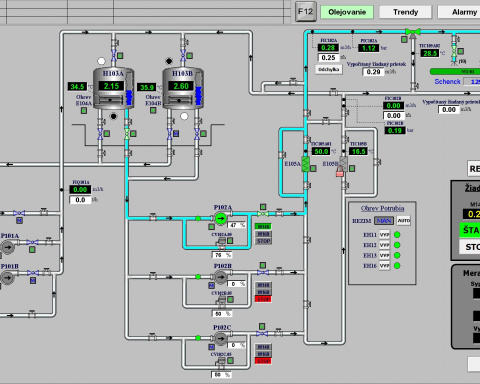

During preparation of the blast furnace charge, the material is sintered on the so-called sintering belts. This means that the conveyor carries a mixture of iron ore, limestone and coke, there are burners above the belt and the transported material must burnt (so-called sintered). In order to burn the entire material properly, it is necessary to create vacuum under it. This vacuum is provided by powerful fans. Since this sintering generates a lot of dust containing various harmful substances, the customer requested to install a filter and a reactor between the sintering belt and the fans to collect dust from the exhaust air and neutralize the harmful substances.

Implemented solution:

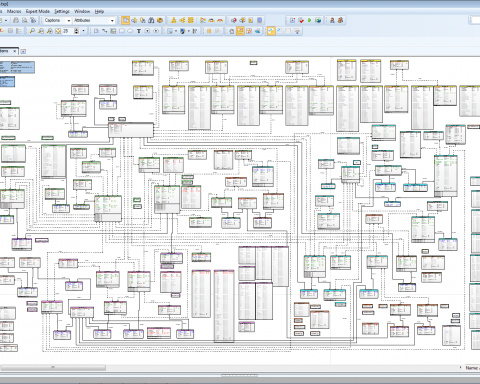

Project delivery, installation and programming of control PLCs for individual parts of the technological process of dedusting of sintering belts and neutralization of harmful substances.

Solutions

Our goal is to provide our customers with a wide-range portfolio of services - from initial consultations, through design, project development, application software development, software development, delivery, installation, testing, staff training, to warranty and post-warranty service and maintenance. Thanks to our offer of complete services we have a long list of satisfied clients.