Oil dosing

Customer request:

In the treatment of the coal charge, a smaller amount of oil at the desired temperature is added to the carbon substrate, which, at optimal dosing, has a favorable effect by forming a thin oil film on the surface of the coal particles. This reduces the total surface tension, which affects the cohesion of the coal grains, and the batch mixture increases its bulk density. The dosing is carried out by spraying directly onto a layer of coal mixture deposited on the conveyor belt via a nozzle. From the operational point of view - transport of the carbon substrate on the conveyor belts, the moistening of the oil affects its surface stiffening, which allows a greater ascendability of conveyor belts. The customer's request was to supply a control system for oil dosing.

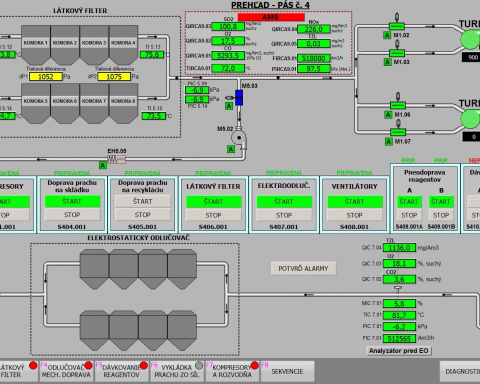

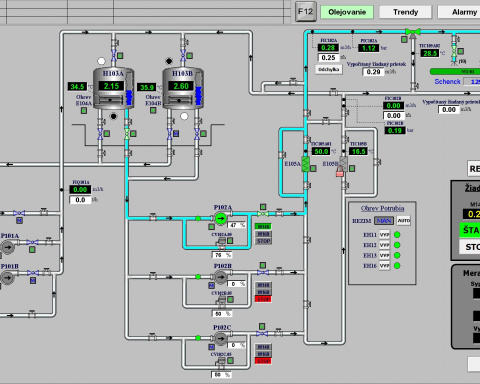

Implemented solution:

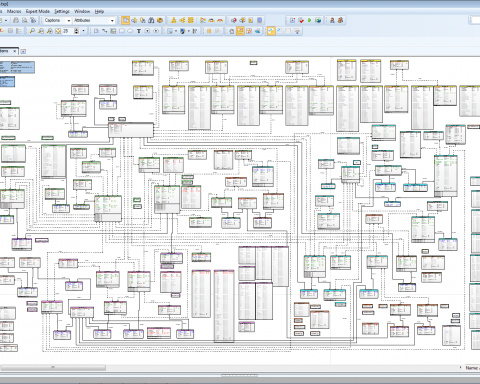

Design, programming and delivery of a complex control system with automatic controllers and visualization for oil dosing and heating, heating of tanks and piping routes, measurement of quantities (flow, levels, temperature, material height), control of pumps, valves, alarm signalling.

Solutions

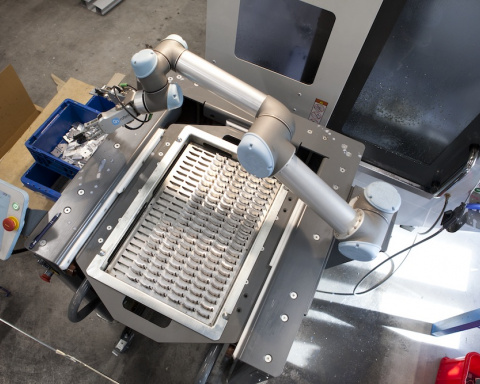

Our goal is to provide our customers with a wide-range portfolio of services - from initial consultations, through design, project development, application software development, software development, delivery, installation, testing, staff training, to warranty and post-warranty service and maintenance. Thanks to our offer of complete services we have a long list of satisfied clients.